The Rise of Industry 4.0: How Machine Technology Is Powering the Next Industrial Revolution Worldwide

White Wang

•

September 19, 2025

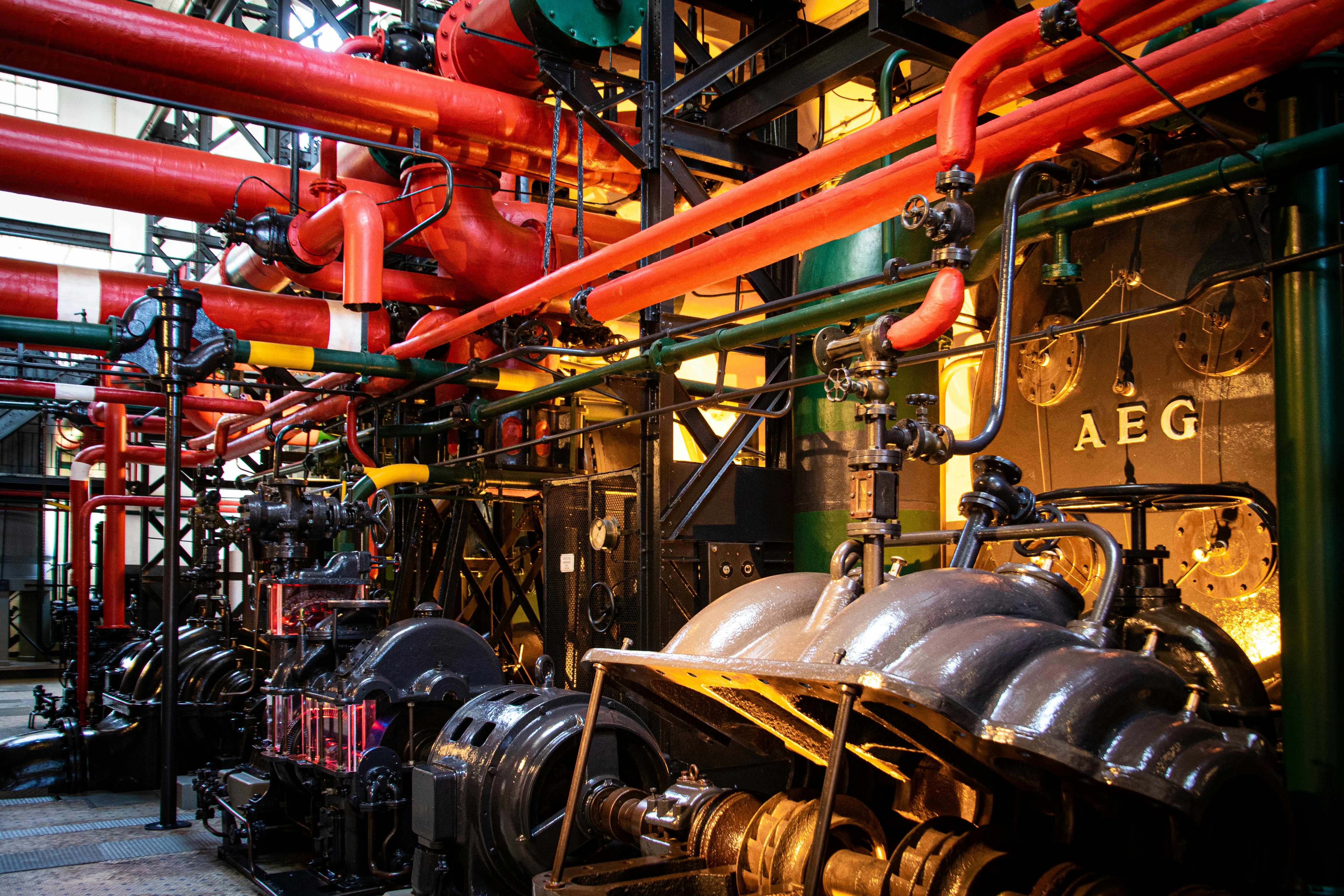

We stand at the precipice of a new industrial age. The first industrial revolution was powered by steam and water. The second brought us mass production and electricity. The third introduced computers and basic automation. Today, the Fourth Industrial Revolution, or Industry 4.0, is upon us, and it is powered by the seamless integration of intelligent machine technology with the physical world.

This is not just an upgrade to the third industrial revolution's digital systems; it is a holistic transformation. Industry 4.0 is creating "smart factories" and interconnected "cyber-physical" ecosystems where machines, processes, and humans communicate and collaborate in real-time. This revolution is creating a new paradigm of manufacturing that is more intelligent, flexible, efficient, and predictive than ever before, and it is unfolding on a global scale.

The Core Technologies Powering Industry 4.0

Industry 4.0 is not a single technology but a convergence of several key machine technologies that, when combined, create a system far greater than the sum of its parts.

1. Cyber-Physical Systems (CPS) and the IIoT

The "technical core" of Industry 4.0 is the Cyber-Physical System (CPS). This is the foundational concept of creating a tight, feedback-driven link between a physical process and its digital controller.

This concept is made reality by the Industrial Internet of Things (IIoT). The IIoT is the "nervous system" of the smart factory—a vast network of sensors, actuators, and connected devices embedded in every machine, robot, and component. These sensors collect a constant, massive stream of real-time data on everything: temperature, vibration, pressure, location, and energy consumption. This data is the "fuel" for the entire Industry 4.0 model.

2. Artificial Intelligence (AI) and Big Data Analytics

If the IIoT is the nervous system, AI is the brain. A single factory can generate terabytes of data per day—"big data" that is impossible for a human to analyze. AI and machine learning algorithms are designed to:

Find patterns in this massive data stream.

Optimize processes in real-time.

Make intelligent, autonomous decisions without human intervention.

Enable predictive analytics, which is the ability to forecast future events based on current data.

3. The Digital Twin: A Virtual Factory

One of the most powerful concepts in Industry 4.0 is the digital twin. This is a dynamic, high-fidelity virtual replica of a physical asset, a production line, or even an entire factory.

It is not just a static 3D model; it is a live simulation. The digital twin is fed a constant stream of real-time data from its physical counterpart's IIoT sensors. This allows companies to:

Run "What-If" Scenarios: A plant manager can test a new production line configuration or a different machine speed in the virtual world to see its effect on output, without stopping the real-world factory.

Train Operators: New employees can learn to operate complex, dangerous machinery in a safe, immersive virtual environment.

Enable Predictive Maintenance: By analyzing the data trends in the digital twin, an AI can predict that a specific motor will fail in the next 72 hours, allowing maintenance to be scheduled before the breakdown occurs.

4. Advanced and Collaborative Robotics (Cobots)

The "muscles" of Industry 4.0 are no longer the "dumb" robots of the past, which were locked in cages to perform one repetitive task. The new generation of robotics is:

Intelligent: Powered by AI vision systems, they can identify, pick, and sort jumbled objects.

Collaborative (Cobots): These robots are designed with advanced sensors to work safely alongside human employees. A cobot can handle the heavy lifting or precise, repetitive bolting, while its human partner performs the final quality check or a task requiring dexterity.

Flexible: Unlike an old assembly line, a cobot can be reprogrammed for a new task in a matter of hours, not weeks.

The Revolutionary Impact of Industry 4.0

This convergence of technologies is not just an upgrade; it is revolutionizing the very nature of manufacturing and logistics.

The Smart Factory and Predictive Maintenance

The "smart factory" is the ultimate outcome of Industry 4.0. It is a fully connected, flexible, and autonomous production environment. Its single greatest benefit is the shift from "reactive" to "predictive" operations.

In a traditional factory, when a critical machine breaks, the entire line stops. Predictive maintenance, enabled by AI and digital twins, has all but eliminated this. By analyzing vibration and temperature data, companies can predict and prevent failures. This single capability has been shown to reduce machine downtime by up to 50% and increase the lifespan of machinery by 20-40%, saving manufacturers billions of dollars. Companies like Siemens and Harley-Davidson have transformed their plants into smart factories, achieving near-perfect quality rates and massive efficiency gains.

The End of Mass Production: The Rise of Mass Customization

For a century, manufacturing was defined by mass production—the ability to make millions of identical items at a low cost. Industry 4.0, with its flexible robotics and AI-driven workflows, enables mass customization.

Because a smart production line can be reconfigured in real-time, a customer can order a product with unique, personalized specifications. The factory's AI will automatically adjust the robotic assembly to produce that one-off item without sacrificing efficiency. The most famous example is the Adidas Speedfactory, which used 3D printing and advanced robotics to produce personalized athletic shoes on-demand.

The Transparent, Intelligent Supply Chain

The revolution extends far beyond the factory walls. Industry 4.0 connects the factory to the entire supply chain.

Real-Time Tracking: IIoT sensors and RFID tags allow a company to track a product in real-time, from the raw material supplier to the final customer delivery.

AI-Powered Logistics: AI analyzes this data, along with weather and traffic, to optimize shipping routes, predict demand with greater accuracy, and prevent bottlenecks before they occur.

A Truly "Worldwide" Revolution

While the concepts are universal, the adoption and leadership of Industry 4.0 are concentrated in global power centers.

Germany: The term "Industrie 4.0" was coined in Germany as part of a high-tech strategic plan to embed cyber-physical systems into its legendary manufacturing sector.

The United States and China: These two nations are currently leading the development and deployment of the core technologies. They account for the vast majority of the world's 5G adoption, over 70% of the world's top AI researchers, and 94% of all funding for AI startups in the last five years. China's "Made in China 2025" initiative is a direct, state-sponsored push to dominate this new industrial landscape.

Developing Nations: For the developing world, Industry 4.0 presents both a massive opportunity and a significant challenge. Without a strong existing manufacturing base and the capital to invest, they risk being left behind, creating a new "digital divide" in global industry.

← Back to Home

This is not just an upgrade to the third industrial revolution's digital systems; it is a holistic transformation. Industry 4.0 is creating "smart factories" and interconnected "cyber-physical" ecosystems where machines, processes, and humans communicate and collaborate in real-time. This revolution is creating a new paradigm of manufacturing that is more intelligent, flexible, efficient, and predictive than ever before, and it is unfolding on a global scale.

The Core Technologies Powering Industry 4.0

Industry 4.0 is not a single technology but a convergence of several key machine technologies that, when combined, create a system far greater than the sum of its parts.

1. Cyber-Physical Systems (CPS) and the IIoT

The "technical core" of Industry 4.0 is the Cyber-Physical System (CPS). This is the foundational concept of creating a tight, feedback-driven link between a physical process and its digital controller.

This concept is made reality by the Industrial Internet of Things (IIoT). The IIoT is the "nervous system" of the smart factory—a vast network of sensors, actuators, and connected devices embedded in every machine, robot, and component. These sensors collect a constant, massive stream of real-time data on everything: temperature, vibration, pressure, location, and energy consumption. This data is the "fuel" for the entire Industry 4.0 model.

2. Artificial Intelligence (AI) and Big Data Analytics

If the IIoT is the nervous system, AI is the brain. A single factory can generate terabytes of data per day—"big data" that is impossible for a human to analyze. AI and machine learning algorithms are designed to:

Find patterns in this massive data stream.

Optimize processes in real-time.

Make intelligent, autonomous decisions without human intervention.

Enable predictive analytics, which is the ability to forecast future events based on current data.

3. The Digital Twin: A Virtual Factory

One of the most powerful concepts in Industry 4.0 is the digital twin. This is a dynamic, high-fidelity virtual replica of a physical asset, a production line, or even an entire factory.

It is not just a static 3D model; it is a live simulation. The digital twin is fed a constant stream of real-time data from its physical counterpart's IIoT sensors. This allows companies to:

Run "What-If" Scenarios: A plant manager can test a new production line configuration or a different machine speed in the virtual world to see its effect on output, without stopping the real-world factory.

Train Operators: New employees can learn to operate complex, dangerous machinery in a safe, immersive virtual environment.

Enable Predictive Maintenance: By analyzing the data trends in the digital twin, an AI can predict that a specific motor will fail in the next 72 hours, allowing maintenance to be scheduled before the breakdown occurs.

4. Advanced and Collaborative Robotics (Cobots)

The "muscles" of Industry 4.0 are no longer the "dumb" robots of the past, which were locked in cages to perform one repetitive task. The new generation of robotics is:

Intelligent: Powered by AI vision systems, they can identify, pick, and sort jumbled objects.

Collaborative (Cobots): These robots are designed with advanced sensors to work safely alongside human employees. A cobot can handle the heavy lifting or precise, repetitive bolting, while its human partner performs the final quality check or a task requiring dexterity.

Flexible: Unlike an old assembly line, a cobot can be reprogrammed for a new task in a matter of hours, not weeks.

The Revolutionary Impact of Industry 4.0

This convergence of technologies is not just an upgrade; it is revolutionizing the very nature of manufacturing and logistics.

The Smart Factory and Predictive Maintenance

The "smart factory" is the ultimate outcome of Industry 4.0. It is a fully connected, flexible, and autonomous production environment. Its single greatest benefit is the shift from "reactive" to "predictive" operations.

In a traditional factory, when a critical machine breaks, the entire line stops. Predictive maintenance, enabled by AI and digital twins, has all but eliminated this. By analyzing vibration and temperature data, companies can predict and prevent failures. This single capability has been shown to reduce machine downtime by up to 50% and increase the lifespan of machinery by 20-40%, saving manufacturers billions of dollars. Companies like Siemens and Harley-Davidson have transformed their plants into smart factories, achieving near-perfect quality rates and massive efficiency gains.

The End of Mass Production: The Rise of Mass Customization

For a century, manufacturing was defined by mass production—the ability to make millions of identical items at a low cost. Industry 4.0, with its flexible robotics and AI-driven workflows, enables mass customization.

Because a smart production line can be reconfigured in real-time, a customer can order a product with unique, personalized specifications. The factory's AI will automatically adjust the robotic assembly to produce that one-off item without sacrificing efficiency. The most famous example is the Adidas Speedfactory, which used 3D printing and advanced robotics to produce personalized athletic shoes on-demand.

The Transparent, Intelligent Supply Chain

The revolution extends far beyond the factory walls. Industry 4.0 connects the factory to the entire supply chain.

Real-Time Tracking: IIoT sensors and RFID tags allow a company to track a product in real-time, from the raw material supplier to the final customer delivery.

AI-Powered Logistics: AI analyzes this data, along with weather and traffic, to optimize shipping routes, predict demand with greater accuracy, and prevent bottlenecks before they occur.

A Truly "Worldwide" Revolution

While the concepts are universal, the adoption and leadership of Industry 4.0 are concentrated in global power centers.

Germany: The term "Industrie 4.0" was coined in Germany as part of a high-tech strategic plan to embed cyber-physical systems into its legendary manufacturing sector.

The United States and China: These two nations are currently leading the development and deployment of the core technologies. They account for the vast majority of the world's 5G adoption, over 70% of the world's top AI researchers, and 94% of all funding for AI startups in the last five years. China's "Made in China 2025" initiative is a direct, state-sponsored push to dominate this new industrial landscape.

Developing Nations: For the developing world, Industry 4.0 presents both a massive opportunity and a significant challenge. Without a strong existing manufacturing base and the capital to invest, they risk being left behind, creating a new "digital divide" in global industry.